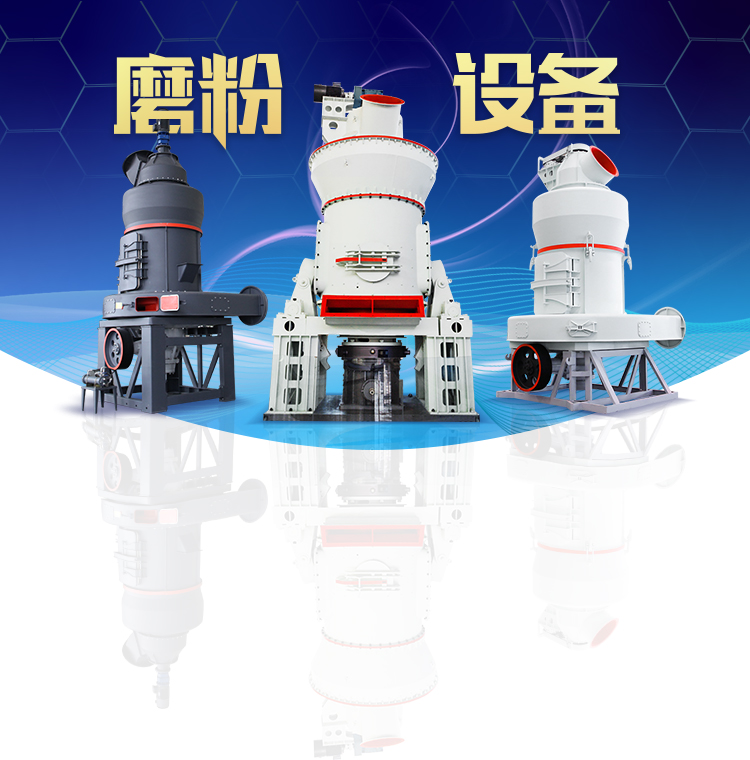

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Secondary Crusher In Cement Plant

.jpg)

Everything you need to know about Crushers in Cement

2017年6月24日 The crushing system with primary gyratory crusher and secondary impact crusher is particularly suitable for compact hard and also abrasive rock With the preceding coarse reduction, it is possible to use crushing tools made of highly wearresisting caststeel in the 2020年7月10日 Secondary crushing, as you can imagine, is the second stage of material processing following its initial reduction At this stage, material will flow through perhaps a second impactor or even a cone crusher, which is effective What Is Primary, Secondary, and Tertiary 2022年2月22日 Impact crusher has unmatched excellent performance is shown in the secondary crushing, tertiary crushing and material recovery Hammer crusher is the best equipment for Cement Manufacturing Technologies DSMAC2019年1月1日 This paper compares the use of jaw and impact secondary crushing for producing coarse recycled aggregates from concrete wastes, obtained from road pavement and Concrete aggregates properties crushed by jaw and impact secondary

.jpg)

The Complete Guide to Primary Crushing,

2023年2月28日 Secondary crushing is the second stage in the comminution process and involves breaking down the material further into smaller pieces that can be handled by the tertiary crushers The purpose of secondary crushing is AGICO offers 4 types of crushers for cement plants: hammer crusher, jaw crusher, impact crusher, and cone crusher The hammer crusher is a kind of crushing machine which uses impact energy to crush materials It is mainly Cement Crusher Crushers for Cement Plant2025年1月14日 However, if the whole cement mining scale is of large size, we usually choose cone crusher or impact crusher to assit jaw crusher and to be secondary or tertiary cement Cement Crushing Grinding Plant, DSMAC dscrusherThe capacity of the cone crusher is usually so large that the feeder can be omitted and the feed tipped directly into the crusher Cone crushers are designed in many versions and sizes, both for primary and for secondary crushing 37 CRUSHING in Cement Industry INFINITY FOR

Types of crusher used in cement industry

2023年5月13日 Roll crushers: These crushers are used for the secondary and tertiary crushing of materials with a compressive strength of up to 200 MPa They are commonly used in the Jaw Crusher Jaw Crusher Machine, Small Jaw Crusher, Portable Jaw Crusher, Jaw Crusher for Sample Preparation Jaw Crusher is a basic sample preparation unit and is essential to address all primary size reduction requirements Jaw Crusher for Cement Plant Quality Control2022年2月22日 Primary Crusher Secondary Crusher There are many types of crushers can be used to primary crushing secondary crushing, such as jaw crusher, impact crusher, hammer crusher, cone crusher It is the main equipment in cement plant to dry the coal powder Read More Crusher Parts The material input, crushing, and other methods are the same Cement Manufacturing Technologies DSMAC2012年4月30日 The secondary crusher (SC) is started together with C2 The objective of this article is the development of a novel raw material mix proportion control algorithm for a cement plant raw mill (PDF) Process Automation of Cement Plant

Grate Cooler – Clinker Cooler AGICO Grate

What Is Grate Cooler? A grate cooler, as a quenchtype clinker cooler, is the important cement equipment in the clinker calcination system Its main function is to cool and transport cement clinker Meanwhile, provide hot air for the AGICO offers 4 types of crushers for cement plants: hammer crusher, jaw crusher, impact crusher, and cone crusher Hammer Crusher The hammer crusher is a kind of crushing machine which uses impact energy to crush Cement Crusher Crushers for Cement PlantRaw materials of the cement plant are mostly from openpit mines, and the ore usually has a large particle size In the preparation of cement raw materials, we first need to crush limestone, gypsum, clay, and other materials into proper Cement Crusher – Crusher In Cement PlantCRUSHER TYPES IN USE In the cement industry, the raw materials undergo primary reduction in single or twinrotor hammer crushers, or impact crushers A typical jaw crusher used at a cement plant quarry is shown in Figure 232 Everything you need to know about cement

.jpg)

rock crusher Aimix Crusher Screening Plant For Sale

As a primary and secondary crusher, it has a strong adaptability to the common local rock and stones 3 One mobile plant can realize the functions of feeding, crushing and screen In concrete batching plants, rock crushers are utilized to provide the necessary aggregate material, which is a crucial component in the production of concreteAIMIX mobile stone crusher plant is a complete set of mobile equipment designed to crush and screen various materials onsite It consists of a vibrating feeder, a jaw crusher, an impact crusher or cone crusher, a vibrating screen, and belt 301200t/h Stone Crusher For Sale In MalaysiaImpact crusher is a kind of crushing machine which uses impact energy to break materials It is suitable for handling brittle materials of medium hardness with side length not exceeding 500mm and compressive strength not exceeding 350 mpaImpact Crusher Impact Rock Crusher AGICO Primary jaw crusher and secondary impact crusher working together in a plant setup The most common primary crusher is a jaw crusher, but, there are many other types including gyratory and cone crushers We will talk about them all What is a Primary Crusher? Machinery Partner

Clinker Cooler Cement Cooler AGICO Cooler

What Is Clinker Cooler? In the calcination process of cement clinker, preheating, calcining, and cooling are three inseparable process links As the supporting equipment of a cement rotary kiln, a clinker cooler (also called cement cooler) 2023年8月29日 In cement plant about 75% electric power is consumed by comminution equipment such as crushers and ball No secondary crusher, it should be fed with 100 mm material Easy adjustment of grinding pressure with the help of hydraulic compression systemOptimizing Electrical Energy Consumption In Cement 2019年9月27日 There are various types of cement crusher on the market, including jaw crusher, cone crusher, hammer crusher, impact crusher, and etc AGICO Cement can provide all types of cement crusher Our cement crusher Cement Euipment Overview Cement Making Hammer mills work with reduction ratios as high as 1:40 to 1:60 as primary and 15:1 as secondary crushers It can be installed for single stage crushing, primary crushing or secondary crushing covering distance from crusher to cement Cement Manufacturing Process INFINITY FOR

Primary Crusher and Secondary Crusher: What They Are and

2023年4月27日 In the dynamic world of cement production, crushers and grinders have become indispensable allies for plant operators seeking to enhance efficiency, reduce costs, and elevate product qualityCrushers and Grinders in Cement Plants LinkedInFor material weighing 16 t/m³ or 100 lbs/ft³ Capacity values are indicative only, crusher performance may vary depending on the feed gradation, feed moisture content,crushability of the material, crusher rpm, installed power and the Portable Secondary Impact Crushers MEKA 2023年11月30日 In a cement plant, crushers are an essential part of the material handling process They are used to reduce the size of large rocks and raw materials into smaller, more manageable pieces that can What is the process of crushers in a cement plant? LinkedIn

.jpg)

How Does Clinker Cooler Reduce Cement

The main power consumption of a clinker cooler is its cooling fans It usually takes 1923 m 3 under standard conditions to cool 1 kg clinker from 1400 ℃ to 65 ℃, and the power consumption of the whole system is about 7 kWh If the APPLICATIONS The strength of Secondary Impact Crusher (MSI) makes them ideal for diverse applications and configurations They have proven their effectiveness in a host of missions from crushing low abrasive materials to Secondary Impact Crushers – MEKA2025年1月14日 So cement is kind of cementitious material which will be of stronger hardness in water Cement mil is used for cement grinding Cement crusher is applied for cement crushing In cement mining, you need to choose suitable cement grinding mill and cement crusher Production process Three stages: 1Cement Crushing Grinding Plant, DSMAC dscrusher4 天之前 As the primary raw material for cement production, reliable limestone supplies are critical for sustainable infrastructure development globally Portable Impact Crusher: Suitable for secondary and tertiary crushing of Limestone Crusher for Efficient Limestone

.jpg)

Detailed Project Report (Technical) On Stone Crusher Plant

Stone Crusher Plant Project Cost / Capital investment: Rs24,16,000 / Production Capacity: 18600 CUM / Year stone crusher (Secondary Machine) for recrushing through Conveyer belt Stone crusher is also required for cement based products like RCC pipes, PSC poles, cement concrete hollow blocks, precast cement concrete slabs, well rings 2019年1月1日 Crusher choice primarily relies on material size, the desired end product, operating costs, and environmental considerations [11] A twocrushing process can be found in European recycling plants, while the choice of a secondary crusher often relies on qualitative criteria such as coarse and fine RCA recovery fractionsConcrete aggregates properties crushed by jaw and impact secondary 3 天之前 Plant contains Kiln of 1200 tpd (Dry Process) grinding of Slag, Cement of 1200 tpd Major plant machineries contain following : Primary Crusher Double Toggle Jaw Crusher, Utkal 400 tph Secondary Crusher, Reversible impact hammerMill, Utkal 250 tph : Raw Mill , Closed circuit tube mill, LT 125 tph :NAYAGAON CEMENT FACTORY CCIThe capacity of the cone crusher is usually so large that the feeder can be omitted and the feed tipped directly into the crusher Cone crushers are designed in many versions and sizes, both for primary and for secondary crushing 37 CRUSHING in Cement Industry INFINITY FOR

.jpg)

Types of crusher used in cement industry

2023年5月13日 Choosing the right type of crusher for the cement industry depends on several factors such as the hardness of the raw materials, the size of the feed, and the desired output size By understanding the different types of crushers available, cement producers can select the best equipment for their specific needs and optimize their production process2022年2月22日 Limestone Crushing Plant For Cement Factory The Advanced limestone crushing line, which includes high efficiency vibrating feeder, highperformance hammer crusher and high abrasion resistance spare parts, has proprietary intellectual property rights and some unique features as follow: 1 Good gravel particle shape, reasonable grade and less grinding Limestone Crushing Plant For Cement Factory DSMACThe crushing system with primary gyratory crusher and secondary impact crusher is particularly suitable for compact hard and also abrasive rock With the preceding coarse reduction, it is possible to use crushing tools made of highly wearresisting caststeel in the secondary crusher (austenitic high alloyed cast iron)Everything you need to know about Crushers in Cement 2020年7月10日 Secondary crushing, as you can imagine, is the second stage of material processing following its initial reduction At this stage, material will flow through perhaps a second impactor or even a cone crusher, which is effective at breaking down these types of materialWhat Is Primary, Secondary, and Tertiary Crushing Eagle Crusher

Cement Manufacturing Technologies DSMAC

2022年2月22日 Impact crusher has unmatched excellent performance is shown in the secondary crushing, tertiary crushing and material recovery Hammer crusher is the best equipment for crushing limestone It can replace the traditional twostage crusher and help to simplify process flow, save infrastructure investment and production costs2019年1月1日 This paper compares the use of jaw and impact secondary crushing for producing coarse recycled aggregates from concrete wastes, obtained from road pavement and demolished building materialsConcrete aggregates properties crushed by jaw and impact secondary MEKA MSI Series Secondary Impact Crusher is ideally suited to crush soft to medium hard materials down to a highly cubical, well graded product size of 080 mm in a single passSecondary Impact Crushers – MEKA2023年2月28日 Secondary crushing is the second stage in the comminution process and involves breaking down the material further into smaller pieces that can be handled by the tertiary crushers The purpose of secondary crushing is to produce a smaller, more uniform product size that can be fed into the tertiary crushersThe Complete Guide to Primary Crushing, Secondary

Cement Crusher Crushers for Cement Plant AGICO Cement

AGICO offers 4 types of crushers for cement plants: hammer crusher, jaw crusher, impact crusher, and cone crusher The hammer crusher is a kind of crushing machine which uses impact energy to crush materials It is mainly composed of shell, rotor, impact iron, lining plate, and screening strips2025年1月14日 However, if the whole cement mining scale is of large size, we usually choose cone crusher or impact crusher to assit jaw crusher and to be secondary or tertiary cement crusher machine Also cement conveyor is used to transport these materials to next procedure, such as vibrating cement screen to screen out required finenessCement Crushing Grinding Plant, DSMAC dscrusherThe capacity of the cone crusher is usually so large that the feeder can be omitted and the feed tipped directly into the crusher Cone crushers are designed in many versions and sizes, both for primary and for secondary crushing 37 The roller crusher This crusher type, shown in figure 312, is used for comminution of soft, sticky andCRUSHING in Cement Industry INFINITY FOR CEMENT EQUIPMENT2023年5月13日 Roll crushers: These crushers are used for the secondary and tertiary crushing of materials with a compressive strength of up to 200 MPa They are commonly used in the cement and mining industries and are designed to handle materials with a Types of crusher used in cement industry

石墨碳酸钙制粉设备求购

--每小时产70T轮胎热解炭黑碳酸钙粉磨粉碎站

--粉磨系统式矿石磨粉机在油页岩粉碎中的应用

--GAW高细立磨GAW高细立磨GAW高细立磨

--贵州04定额机械粉碎

--冷却微粉磨器

--140岩沥青磨粉机型号图

--山西省代县富祥方解石矿

--粉碎雷蒙磨制一方沙要多少成本

--鞍山高细立磨子

--建渣碳酸钙粉碎

--吸水率大的碳酸钙重质碳酸钙

--生石灰设备工艺流程生石灰设备工艺流程生石灰设备工艺流程

--雷蒙磨大概什么价格

--山东大理石应急落板及粉碎设备

--重钙磨粉机雷蒙机C110 参数

--流纹岩粉石机

--什么是水力轴承

--全国的球磨机

--开办石膏厂

--毫米目换算

--石头磨粉的视频

--T石灰石用矿石磨粉机

--找破精品砂粉设备石灰石

--滚筒生石灰制粉机械

--褐煤煤立磨规格

--中速磨煤机计划性检修

--哪里有卖石灰石雷蒙磨电解铝废渣磨粉机碳酸钙磨粉机

--偏心 突起

--智利方解石矿

--